Different Types of Reactors and Applicable Impeller Structures

| Reactor type | Feature | Common propellant type | Suitable resins for production |

| Stainless steel jacket reactor | Uniform heat transfer, suitable for high-temperature and high-pressure operations | Paddle, anchor, frame | Epoxy resins, phenolic resins, alkyd resins |

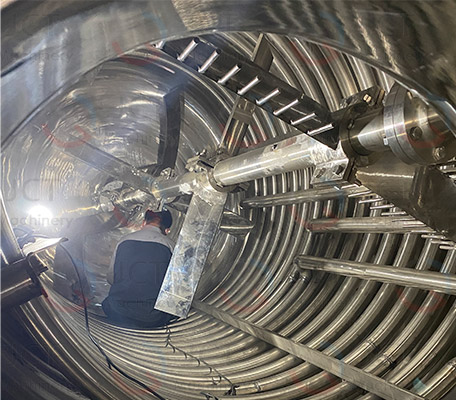

| External coil reactor | Large heat transfer area, suitable for high-temperature polycondensation reactions | Anchor+frame combination | Unsaturated polyester resins, alkyd resins |

| Internal coil reactor | High internal heat exchange efficiency, more precise reaction temperature | Frame, ribbon | Acrylic resins, polyurethane resins |

| Vacuum reactor | Capable of dehydration, degassing and solvent removal | Ribbon, pusher | Waterborne resins, acrylic emulsions, PVA glue |

Analysis of Impeller Types and Mixing Characteristics

1. Anchor type

Structure: Rotates around the kettle wall, resembling a ship's anchor.

Characteristics: Suitable for medium to high viscosity materials; scrapes the kettle wall to prevent coking.

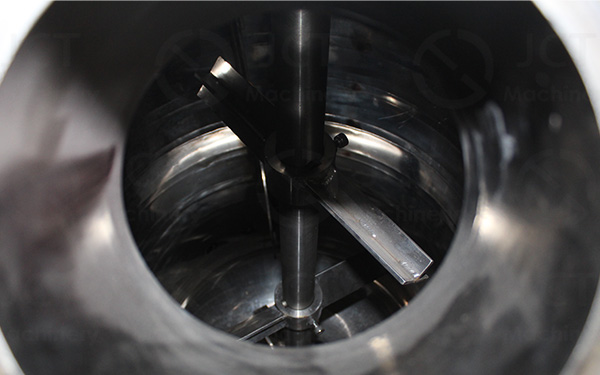

2. Frame type

Structure: Similar to a rectangular frame, with wide blades.

Characteristics: Uniform mixing, low shear; suitable for reaction systems with large viscosity variations.

3. Propeller type

Characteristics: High shear force, good flowability; suitable for low viscosity systems.

4. Ribbon type

Characteristics: Circulates material vertically, preventing stratification.

If the type of reactor and impller does not match the characteristics of the material, it will directly affect the reaction efficiency, product quality, and may even load to equipment damage or safety hazards.

Guangdong JCT Intelligent Technology Co., Ltd is professional in resin production line equipment manufacturing for 20+ years. Feel free to chat with us if you are interested in resin production: +86-181 3837 3963 (Whatsapp, Wechat) or george820606@gmail.com.

Home

Home JCT

JCT  Oct 29,2025

Oct 29,2025

Why Is Reactor The Main Equipment In Resin Production Line?

Why Is Reactor The Main Equipment In Resin Production Line?