1. From a production principle perspective: Resin is essentially the "resin of a chemical reaction".

Resins (such as unsaturated polyester resins, epoxy resins, acrylic resins, phenolic resins, etc.) are essentially macromolecular polymers generated through chemical reactions.

These reactions include:

- Condensation polymerization

- Addition polymerization

- Crosslinking reaction

- Modification reaction

To ensure these reactions proceed safely, controllably, and stably, equipment capable of providing:

Reactor: A device with functions including heating, cooling, stirring, sealing, vacuuming and pressure control.

Therefore, reactor is the only main equipment for achieving the main step of "monomer to resin".

2. From the perspective of equipment function: Reactor integrates all the main operations required for resin production.

| Main function | Description |

| Heating | The polymerization reaction is heated to the required temperature (120~250℃) via jacket or coil heating (heat transfer oil, electric heating, steam) |

| Cooling | When the polycondensation reaction is complete or temperature control is required, the cooling water is switched to prevent overheating and decomposition |

| Stirring | Uniform mixing, heat transfer, and uniform reaction are achieved through different impeller types (anchor, frame, ribbon, propeller, etc.) |

| Vacuum and dehydration | Dehydration and solvent removal are often required during resin reactions; reactor can be equipped with a vacuum system for efficient degassing |

| Feeding and discharging | Precise feeding and safe discharge are achieved through metering tanks or reflux condenser lines |

| Pressure and safety control | Reactor body is pressure-resistant and equipped with safety valves and explosion-proof devices to ensure safe high-temperature reactions |

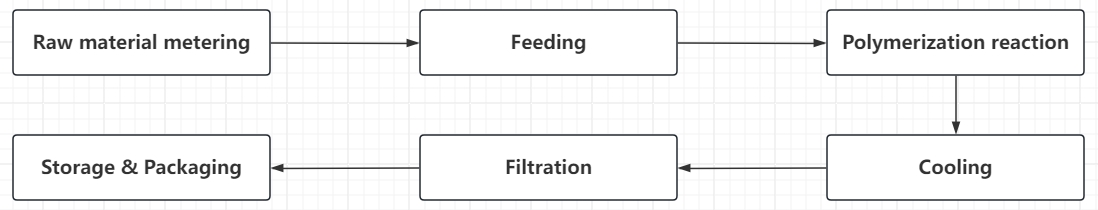

3. From a process flow perspective: Reactor is the "main node" of the resin production line.

The general process of a resin production line is as follows:

Reactor determines main indicators such as the degree of polymerization, molecular weight, viscosity and color.

Subsequent processes (dilution, mixing, filtration) are merely physical treatments.

Therefore, reactor directly determines the quality of the resin product.

4. From an economic perspective: Reactor efficiency determines capacity and energy consumption.

The capacity of resin production line is mainly determined by the volume of the reactor and reaction cycle.

Energy consumption and cost are determined by the heat transfer efficiency and stirring efficiency of the reactor.

High-quality reactor can shorten reaction time by 20-40%, save energy, and ensure product consistency.

Reactor is the "heart" of the resin production line. It determines whether the reaction can proceed fully, safely, and in a controllable manner, and also determines the performance and stability of the final resin product.

Home

Home JCT

JCT  Nov 03,2025

Nov 03,2025

Smart Manufacturing Solutions For Polyurethane Resin Production Line

Smart Manufacturing Solutions For Polyurethane Resin Production Line