Unsaturated polyester resin (UPR): A thermosetting resin containing carbon-carbon double bonds (C=C) in the main chain, which needs to be crosslinked and cured after adding an initiator.

Polyester resin (generally refers to thermoplastic polyesters, such as PET/PEs): Thermoplastic plastic or coating base material that does not contain double bonds and can be melt-processed.

Difference in Application Scenarios

| Application areas | Unsaturated Polyester Resin | Polyester Resin |

| Fiberglass / composite materials | Main materials | x |

| Powder coating | x | Saturated type with main resin |

| Hot melt glue | x | TPU or polyester hot melt glue masterbatch |

| Gel coat / Artificial stone | Highly reactive, used with initiator | x |

| Industrial coating / plastic modification | High solid content systems (such as high gloss PU paint) | Can be used for PU coating and plastic toughening |

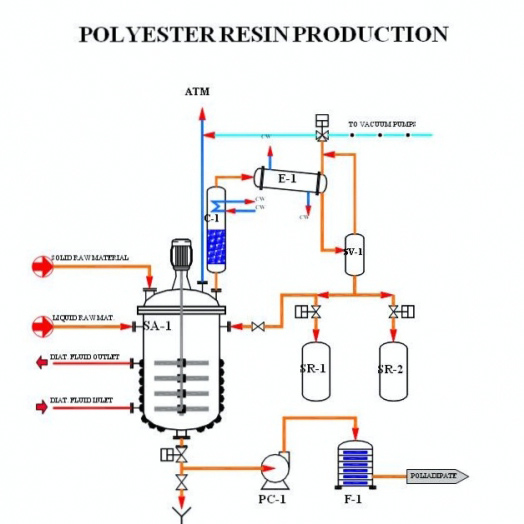

Comparison of Production Line Equipment Difference

| Project | Unsaturated Polyester Resin Production Line | Polyester Resin Production Line |

| Reactor Type | Reactor with heating jacket / inner coil (anti-corrosion) | Jacket heating reactor or sigma mixer |

| Process Temperature | 150-220℃ | 180-250℃ (higher temperature) |

| Dilution Steps | Need to be diluted with styrene to form a liquid system | No dilution is required, the product is solid or viscous |

| Post-processing Equipment | Filter, cooler, vacuum system, storage tank | Extruder, film cooling belt, pelletizer |

| Environmental Protection Requirements | Styrene has VOC emissions (need condensation recovery) | Less volatiles, relatively environmentally friendly |

| Control Method | Medium degree of automation, focusing on temperature and acid value control | Higher automation, suitable for high temperature and viscous material speed and shear control |

Differences Between Production Process

Unsaturated Polyester Resin: The dibasic acid and diol are reacted to form oligomers through esterification reaction, and then styrene monomer is added for dilution to form a cross-linkable liquid resin. The final product of this process is a viscous liquid resin that can be directly filled into barrels or storage tanks for use without melt granulation.

Polyester Resin: Usually, a high-temperature polycondensation process is used to first react terephthalic acid (PTA) and ethylene glycol to form oligomers, and then continue to poltmerize under high temperature vacuum to form high molecular weight polyester. Finally, after melt extrusion, strand drawing, cooling and pelletizing, a solid granular product is obtained. This process not only has higher temperatures, but also must be equipped with strand granulation and drying equipment.

Home

Home JCT

JCT  May 20,2025

May 20,2025

Different Resin Products And Recommended Blade Types

Different Resin Products And Recommended Blade Types