Reactors can be used in the production of a variety of resin products, but the production of dental resins requires a vertical kneader.

The characteristics of dental resin determine special requirements for mixing equipment.

1. Extremely high viscosity

Dental resin is often high-viscosity materials with high molecular structures (especially thermoplastic or thermosetting resins), which will form a viscous or even semi-solid state during reaction or mixing.

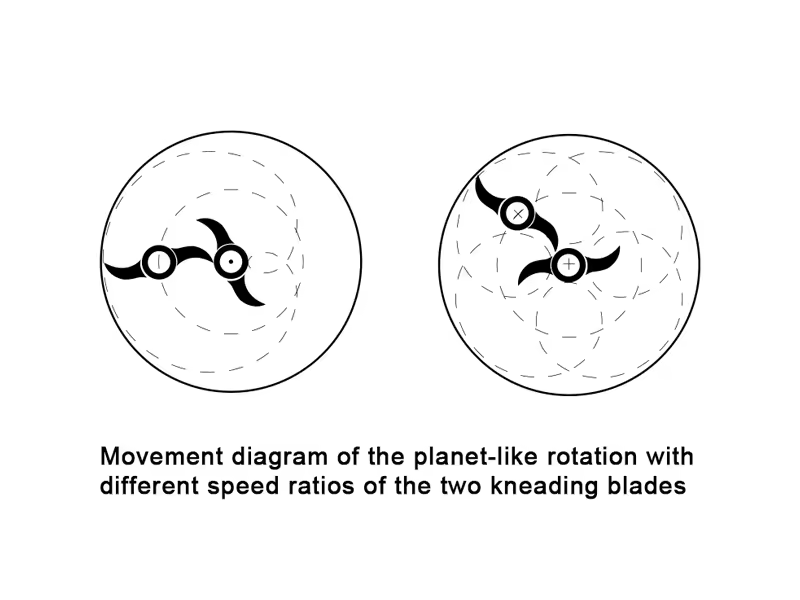

Vertical kneader is equipped with a powerful double S-shaped stirring paddle, which can directly stir high-viscosity/elastic materials with higher efficiency.

The stirring paddles of reactor are mostly paddle-type or anchor-type, with limited stirring force. When encountering viscoelastic materials, it is easy to "fail to stir" or form a "stirring dead corner".

2. Avoid air bubbles

Dental resin is ultimately used in the oral cavity and must be dense and free of bubbles. If air is entrained during the mixing process, it will affect the performance after hardening.

Vertical kneader can knead under vacuum to effectively remove air.

Even if the reactor is equipped with a vacuum device, it is difficult to completely remove the microbubbles formed during mixing.

3. Most dental resins are "heat-sensitive" system

Dental resin has high requirements for temperature control. If the reaction/cross-linking process is overheated, it will lead to premature curing, coking or performance degradation.

Vertical kneader jacket heat transfer oil circulation + low speed shearing, precise temperature control, avoid local high temperature.

Reactor is prone to "local hot spots" under high viscosity conditions, and it is difficult to control the temperature evenly.

4. Small batches and sanitary structure requirements

Most dental resins are high value-added, small batch products, and have extremely high requirements for equipment cleanliness.

The mixing cylinder of JCT vertical kneader adopts a stainless steel liner + mirror polishing process, which can be pushed and pulled to facilitate discharging and cleaning, and is adapted to medical and health standards.

Reactor is complicated to clean and has many dead corners, which is not conducive to multiple batches of production.

Advantages and Highlights of Vertical Kneader

1. High shear mixing ability

Specially designed for high viscosity dental resin, ensuring uniform distribution of filler and resin, no agglomeration and no stratification.

2. Vacuum bubble-free process

Avoids resin from entraining air, improves density and aesthetics after curing, and is suitable for precision scenes such as dental molds.

3. Precision temperature control system

Jacket + thermocouple linkage ensures that polymerization or heating does not cause coking or premature maturation.

4. Hygienic and clean design

Mirror polished inner wall for easy cleaning and material replacement, meeting medical-grade equipment specifications.

5. Multiple discharging forms

Optional flip cylinder/side discharge/screw discharge, suitable for dental materials with different rheological states.

If you are interested in vertical kneader (capacity can be customized), feel free to contact us:

Home

Home JCT

JCT  May 09,2025

May 09,2025

Difference Between Unsaturated Polyester Resin And Polyester Resin Production Line

Difference Between Unsaturated Polyester Resin And Polyester Resin Production Line