What is phenolic resin?

Phenolic resin is a thermosetting resin produced by the polycondensation reaction of phenols and formaldehyde. It exhibits high heat resistance, chemical resistance, mechanical strength, and electrical insulation. It is widely used in industries such as brake pads, abrasives, refractories, bakelite, coatings, and adhesives.

Phenolic Resin Production Line Equipment Configuration

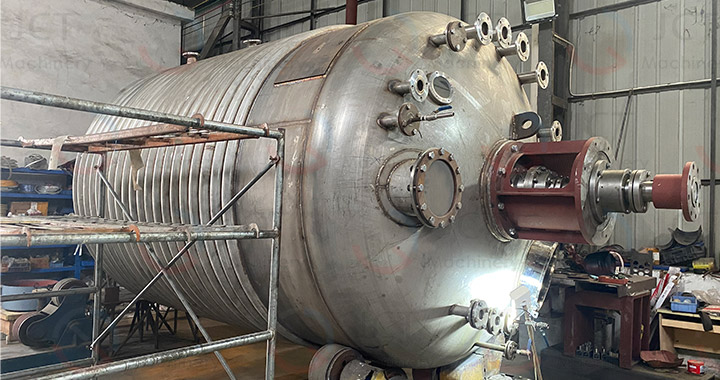

1. Reactor

Used to complete the polycondensation reaction of phenols and formaldehyde.

Typically, stainless steel reactors are used, equipped with heating, cooling,stirring and vacuum dehydration functions.

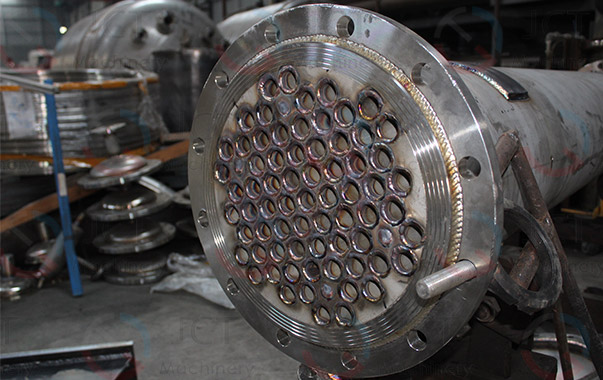

2. Condenser

Used to cool the steam and water generated during the reaction and recover formaldehyde and by-products.

3. Vacuum system

Dehydrates and lowers the boiling point in the later stages of the reaction, accelerating the polycondensation reaction and improving resin quality.

4. Storage tank/metering system

Used for storing and accurately metering raw materials (phenol, formaldehyde and catalyst).

5. Piping and automatic control system

Enables automatic feeding and precise temperature and pressure control to ensure product consistency.

6. Post-processing equipment

Includes cooling, granulation or solution preparation systems to meet the diverse needs of powdered, liquid or flake phenolic resins.

JCT ensures stable production and product quality of phenolic resin.

Process Control

- Temperature control: Reactor is equipped with a precise heating/cooling system (such as thermal oil, electric heating or jacketing) to prevent overheating and underreaction.

- pH adjusting: The dosage of acid and base catalysts must be precise to control the polycondensation rate and resin molecular weight distribution.

- Stirring uniformity: An appropriate impeller type (anchor , paddle or propeller) ensures thorough mixing of the materials and prevents localized overreaction.

Equipment Assurance

- High-quality reactor: Corrosion-resistant material (stainless steel), with a mirror-polished interior to minimize residue.

- Vacuum system: Controls the discharge of moisture and by-products to prevent degradation of resin performance.

- Automated control system: A PLC and touch screen system enable real-time monitoring and recording of temperature, pressure and speed.

Choosing JCT's phenolic resin production line not only enables fully automatic and precise control of temperature, pressure and pH, but also ensures high stability and high-quality performance of resin products through online detection and a complete vacuum dehydration system.

Home

Home JCT

JCT  Sep 19,2025

Sep 19,2025

About PU Resin Production Line

About PU Resin Production Line