1. Reactor

Purpose: Main equipment for chemical processes such as raw material heating, reaction, polycondensation or esterification.

Configuration: Equipped with an agitator (anchor, paddle, frame or turbine), heating system (thermal oil, electric heating or steam), cooling system, and vacuum system.

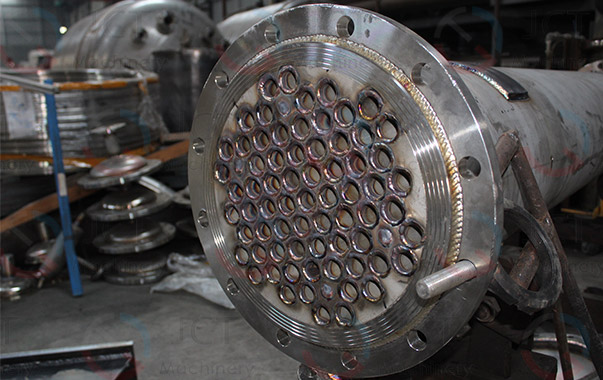

2. Condenser

Purpose: Cools and recovers water, solvents, or by-products generated during the reaction.

Configuration: Shell-and-tube or coil-and-tube, selected based on the process.

3. Water separator

Purpose: Separates water or alcohol generated during the reaction.

Typical Application: Dehydration in the production of unsaturated polyester resins and alkyd resins.

4. Metering and dosing system

Purpose: Precisely control the addition of various monomers, additives, and catalysts.

Type: Manual dosing, automatic weighing and feeding system (liquid metering pump, automatic powder feeder).

5. Vacuum system

Purpose: Lower reaction temperature, accelerate dehydration reaction, reduce side reactions, and ensure product clarity and performance.

Components: Vacuum pump, condenser, buffer tank.

6. Cooling system

Purpose: Rapidly cool the materials after the reaction to avoid over-reaction or side reactions.

Configuration: Cooling coil, chiller.

7. Storage and intermediate tanks

Purpose: Raw material storage, temporary storage of finished resin.

Configuration: Stainless steel or carbon steel, some require anti-corrosion lining.

8. Filtration system

Purpose: Remove impurities and improve resin purity and stability.

Resin production line equipment is centered around a reactor, complemented by supporting condensation, water separation, vacuum, cooling, filtration, storage, and filling systems, forming a complete production process.

As a professional chemical equipment manufacturer, JCT can provide customers with turnkey projects for various resin production lines, including design, manufacturing, installation, commissioning, and technical formulation support.

Home

Home JCT

JCT  Sep 17,2025

Sep 17,2025

Stable Phenolic Resin Production Line

Stable Phenolic Resin Production Line