What is high speed disperser?

High speed disperser is an industrial equipment specially used for rapid wetting, dispersion and uniform mixing of solid powder in liquid-solid system. It is widely used in paint, coating, adhesive, ink, resin, cosmetics, pesticide and other industries.

High speed disperser working principle

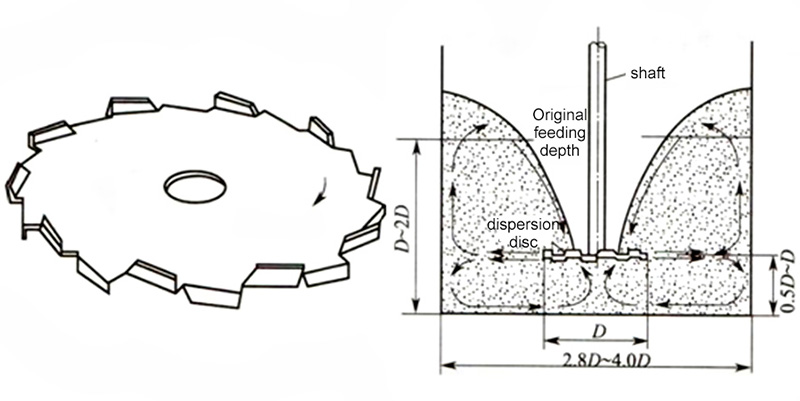

High speed disperser uses a high-speed rotating dispersing disk (usually a serrated disk) to generate strong shear force and turbulence in the liquid, quickly breaking up the powder and dispersing it into the liquid phase to form a stable mixture.

- The motor drives the dispersion shaft to rotate at high speed

- Dispersing disc cust the liquid and forms a turbulent zone

- The powder is sucked into the dispersing disc area under suction

- It is broken up and dispersed under strong shear and impact force

- The material circulates in the tank, rises, falls and is mixed by convection

Daily maintenance of high speed disperser (per shift/per day)

| Clean appearance | Remove residual materials on the machine body, dispersing disc and shaft (pay special attention to pigment accumulation) |

| Check seals | Observe the leakage at the mechanicla seal (solvent-based equipment should be ≤3 drops/minute) |

| Lubrication point filling | Add grease to the lifting guide rail and bearing seat (lithium-based grease NLGI2 grade) |

| Tighten bolts | Check whether the dispersing disc fixing bolts and anchor bolts are loose (torque must comply with the equipment manual) |

| Electrical inspection | Confirm that the emergency stop button and inverter heat dissipation are normal, and there is no abnormal alarm code |

Regular maintenance of high speed disperser (monthly/quarterly)

1. Mechanical system

Disperser wear detection

- Use a caliper to measure the height of the saw teeth. If the wear exceeds 20% of the original thickness, it must be replaced.

- Severe wear will cause the shear force to drop by more than 30%.

Bearing replacement

- Replace the spindle bearing every 3000 operating hours or 2 years.

- Dynamic balance test is required after replacement (vibration value ≤2.8mm/s).

2. Hydraulic lifting system

| Fault phenomenon | Possible cause | Solution |

| Lifting jam | Guide rail lacks oil/deforms | Clean the rail + replace the hydraulic oil |

| Lifting is not synchronized | Cylinder seal is aging | Replace the seal (solvent-resistant fluororubber) |

High speed disperser common trouble shooting guide

| Fault | Quick diagnosis | Professional solution |

| Abnormal vibration |

1. Loose dispersing disc 2. Damaged bearing |

Retighten or replace bearing (dynamic balancing is required) |

| Too high temperature temperature |

1. Insufficient cooling 2. Overload |

Check cooling water flow, reduce load or upgrade motor |

| Unstable speed |

1. Inverter failure 2. Voltage fluctuation |

Calibrate inverter parameters and install voltage stabilizer |

| Leakage |

1. Seal aging 2. Shaft wear |

Replace mechanical seal and repair shaft neck (spray tungsten carbide) |

Safety operating red lines for high speed disperser

- No-load operation is strictly prohibited (will cause dry grinding and burning of mechanical seals).

- Overspeed operation is prohibited (the speed must not exceed the nameplate calibration value).

- Cleanup must be performed after complete shutdown (to prevent shear damage).

Home

Home JCT

JCT  Jul 16,2025

Jul 16,2025

Pressing Machine And Vacuum Pressing Machine

Pressing Machine And Vacuum Pressing Machine