Dental resins (such as paste-like light-curing resins, denture restoration resins, etc.) exhibit high viscosity, easy temperature rise, and easy bubble inclusion during the production process. Ordinary stirring or dispersing equipment cannot achieve the multiple requirements of uniform mixing + vacuum degassing + low temperature control + high viscosity transportation, so vertical kneader must be used for mixing and preparation.

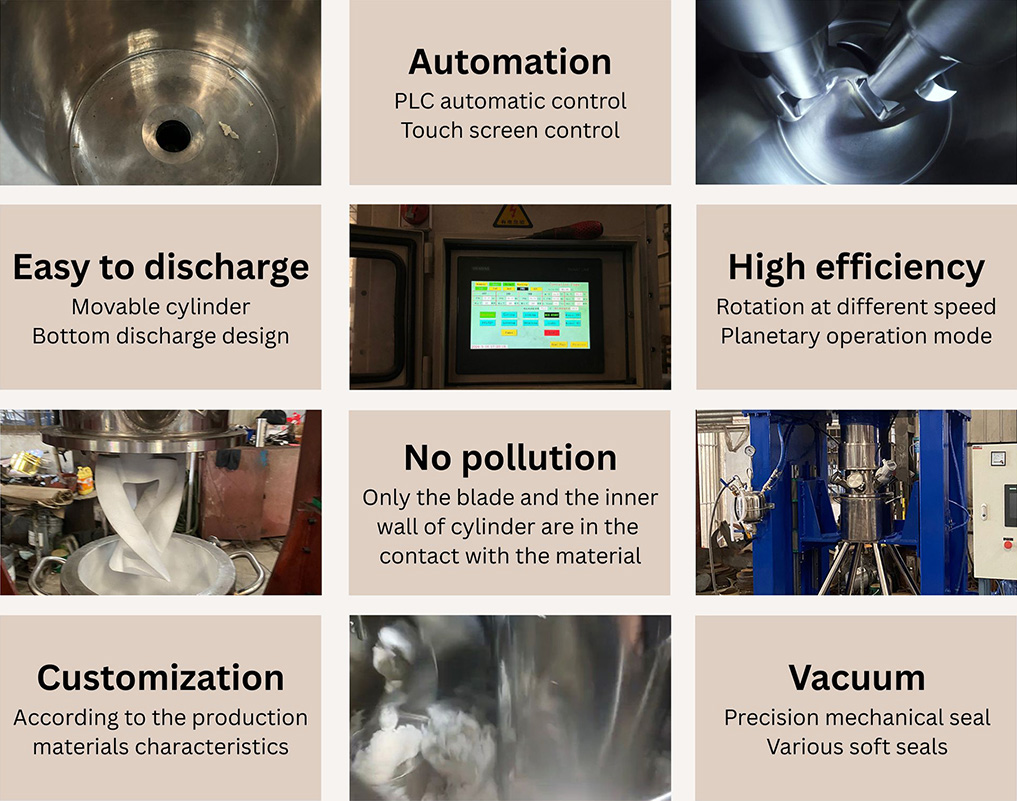

1. Strong mixing of high viscosity materials

The duplex stirring paddle structure is used to operate at high torque and low speed in a vertical closed chamber, which can effectively mix high-viscosity materials up to 1 million cP, such as dental composite pastes, restorative material bases, etc.

2. Vacuum degassing function

Vertical kneader is equipped with a vacuum system, which continuously evacuates during the mixing process to remove air and suppress bubble residues. Vertical kneader is especially suitable for dental materials that are extremely sensitive to bubbles.

3. Precise temperature control system

The jacket can be heated/cooled by water or oil, and the temperature can be controlled within the range of ±1℃ to prevent the material from prematurely curing or performance degradation due to local overheating.

4. Sealed and clean production

Vertical kneader is mostly designed with bottom discharge, and the mixing cylinder can be pushed out, without residue and easy to clean. It can meet the GMP-level clean requirements in the medical/dental field, and the material is mostly SS316.

1. Raw material storage and premixing tank

Estimated amount of monomer resin, filler and additives.

2. Vertical kneader

With vacuum + temperature control system, the whole mixing process is closed. Because it is a vertical structure, the shaft of the stirring paddle will not touch the mixed material and will not cause pollution.

3. Hydraulic discharge system

Automatic extrusion of high-viscosity materials.

4. Transfer tank or storage barrel

Prepare for filling or further processing.

5. Filling system

Quantitative filling into small packages such as syringes, hoses and plastic bottles.

**Optional supporting facilities such as cooling water circulation system and dust removal device can meet the high standards of quality and cleanliness in the dental industry.

| Advantages | Description |

| Strong viscosity adaptability | Can handle high-viscosity pastes from 50,000 to 1,000,000cP |

| Precision manufacturing process | The blades and cylinder are fully mirror-polished, meeting medical/dental standards. Special coating configurations can also be made according to customer needs |

| Vacuum + temperature control + hydraulic integration | Achieve bubble-free, dead-angle-free, pollution-free operation |

| Rich export experience | Has been exported to Egypt, Iran, Pakistan and other countries |

| Support experimental line construction | Provide small experimental line equipment for early process development |

JCT not only provides single equipment, but also can customize the entire dental resin production line for you, including material selection, equipment configuration, process debugging and on-site installation services.

Phone: +86-181 3837 3963 (Whatsapp, Wechat)

Email: george820606@gmail.com