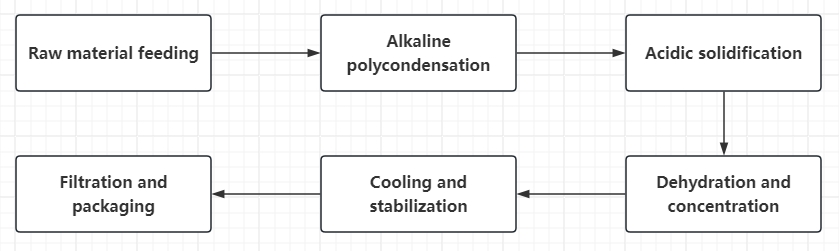

Urea-formaldehyde resin is a low-cost, high-bonding-strength thermosetting resin, mainly used in the fields of artificial boards (such as plywood, density boards), wood adhesives, etc.

| Raw material | Function |

| Urea | Main reaction monomer |

| Formaldehyde | Condensation with urea |

| Sodium hydroxide | Initial pH adjustment |

| Formic acid / ammonium chloride | Acidic curing stage catalyst |

| Melamine | Modifier, reduce formaldehyde release, improve water resistance |

| Polvinyl alcohol | Thickener, improve initial viscosity |

The core advantages of JCT's urea-formaldehyde resin production line lie in environmental compliance, energy consumption control and intelligent production, while helping customers improve product performance through formulation and process innovation.

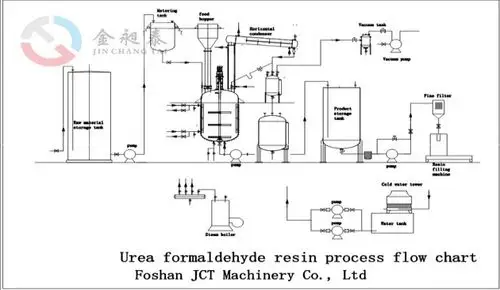

1. Reactor

It is the main equipment to realize the hydroxymethylation and condensation reaction of urea and formaldehyde.

2. Condenser

Recover formaldehyde, water vapor, etc. that escape from the reaction to reduce energy consumption and pollution.

3. Metering tank

Store formaldehyde solution, urea, alkali solution, acid solution and other reaction raw materials.

4. Vacuum system

Reduce the reaction temperature, improve product quality, suitable for some resin varieties.

5. Cooling system

Control the heat release of condensation reaction and keep the reaction temperature stable.

6. Automatic feeding system

Precisely control the feeding order and flow of formaldehyde, urea, acid and alkali and other raw materials.

7. Glue storage tank

Temporarily store the synthesized urea-formaldehyde resin for filling or transportation to the use point.

8. Waste gas treatment system

Treat formaldehyde waste gas to prevent pollution.

9. Wastewater temporary storage/treatment system

Collect cleaning water, ground water, reactor condensate, etc.

10. Heating system

Provide the heat energy required for the reaction, generally using a thermal oil system or a steam system.

11. Centrifugal pump/transfer pump

Transport raw materials, finished resin, cooling water, etc.

12. Cleaning system (CIP)

Cleaning the inside of the equipment to reduce residue and prevent cross contamination.