DOP is a common plasticizer primarily used to plasticize PVC resins. It is widely used in cables, hoses, artificial leather, floor coverings, adhesives and coatings.

1. Imparts flexibility

Resin molecular chains interact strongly, making them less mobile. DOP molecules penetrate the intersegmental gaps between resin chains, weakening the intersegmental forces and making them more flexible.

2. Improves processability

DOP lowers the resin's glass trasition temperature and viscosity, making it easier to flow and shape during processing. This facilitates processes such as extrusion, injection molding, and calendering.

3. Enhances low-temperature resistance

Resins tend to become brittle at low temperatures. DOP maintains their flexibility and improves low-temperature performance.

4. Adjusts performance balance

While DOP improves flexibility, it also reduces the resin's hardness and strength. In practical applications, DOP is often used in combination with other plasticizers to achieve a balanced performance balance.

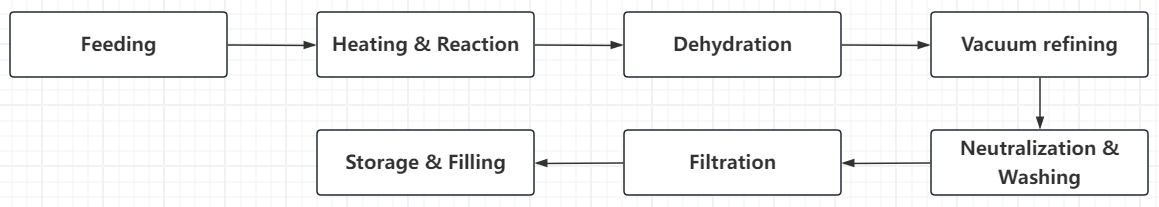

Choose JCT's DOP production line turnkey project will give you efficient equipment, mature technology, and comprehensive service. You will quickly build your plant, achieve stable production, and seize market opportunities.