Acrylic coating is widely used in construction, automobiles, industrial corrosion protection and other fields due to their excellent weather resistance, color stability and environmental protection.

As a manufacturer with 20 years of experience in coating equipment manufacturing, JCT provides acrylic coating production line turnkey project from raw material pretreatment to finished product filling, helping customers achieve efficient and low VOC production.

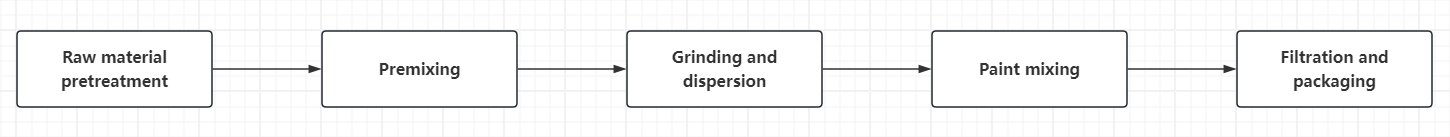

1. Raw material metering system

Precisely meter raw materials such as resin, additives, pigments and fillers to ensure formula consistency.

2. High speed disperser

Preliminary mixing of pigments and fillers to form a uniform slurry.

3. Sand mill (optional)

Fine grinding to improve the fineness and gloss of the coating (especially important in the color paint system).

4. Reactor

Used for acrylic resin prepolymerization or functional modification in certain systems.

5. Paint mixing tank

Mixing, color matching, viscosity and performance parameters adjustment.

6. Filtration system

Remove impurities and improve coating stability.

7. Vacuum degassing device (optional)

Defoaming, removal of volatiles, and improvement of product purity.

8. Filling machine

Automatic quantitative packaging to improve efficiency and ensure pollution-free.